These days you keep hearing about predictive maintenance and how valuable it is. It’s the utopia where equipment operators can anticipate impending malfunctions, preemptively schedule repairs, minimize disruption to factory operation, and, most importantly, protect equipment from catastrophic failures. With bright eyes, we can all agree on the value of predictive maintenance, or should I say the expected value of predictive maintenance?

When it comes to talking about in-production implementations of predictive maintenance on equipment in the field, our bright eyes quickly lose their shimmer. It turns out that few companies have actually implemented predictive maintenance in operation, leading to the question, why is this the case?

Throughout conversations with industry leaders, there is a consistent theme of the four key challenges that equipment builders and operators have to overcome to successfully work with the data science community and implement predictive maintenance solutions in operation:

1. Fostering collaboration to leverage the existing domain know-how while designing the algorithms. How can companies help foster collaboration between data scientists and domain experts so that powerful algorithms for predictive maintenance based on statistics methods in combination with domain knowledge are designed? How can data scientists and domain experts collaborate closely with each other to ensure that the key components of every powerful predictive maintenance application — data analytics methods and domain knowledge — are fully leveraged?

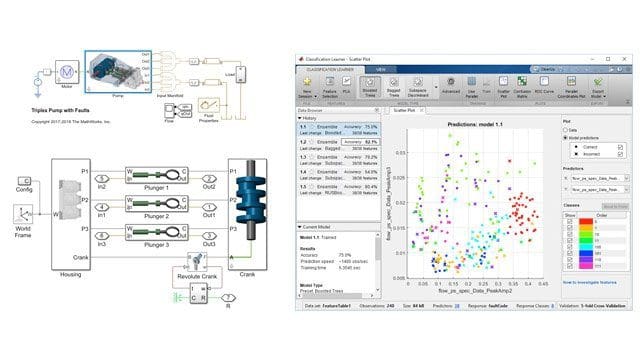

Successful predictive maintenance applications combine both: statistics-based data analytics methods, like machine learning, as well as the domain expertise that the R&D engineers have about their equipment (in many cases, already captured in simulation models). Approaching predictive maintenance with a pure data analytics approach will miss-out on important information held within the engineering and operations teams that build and support the equipment.

2. Training the algorithms in the absence of failure data. A key aspect of machine learning is to train the algorithm on data from the field. This includes “good” data from uneventful production use as well as failure data captured for the various error scenarios that can occur while operating the equipment. But where can you get the failure data when the objective is to never allow the equipment to break in the first place?

For organizations applying predictive maintenance to industrial systems ranging from wind turbines to air compressors, this is becoming an increasingly important riddle to solve. As a way out of this dilemma, simulation models can be used to generate synthetic failure data to train the algorithms in the absence of measured failure data from the field.

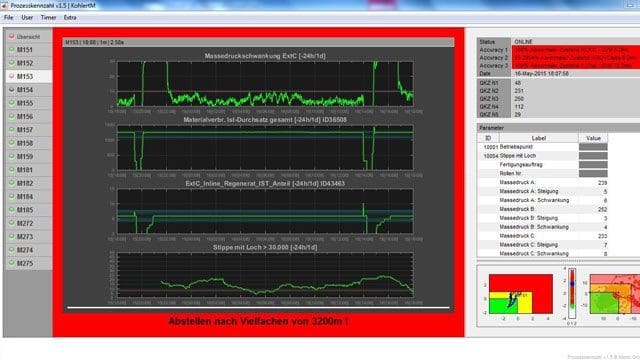

3. Deploying the algorithms for in-operation use. Once the predictive maintenance algorithm has been designed and trained on the desktop, it needs to be deployed on the equipment. The effort for this step highly depends on the IT and OT infrastructure in place. While some algorithms are implemented on a real-time hardware platform (e.g., on an embedded controller, an industrial PC, or a PLC), others will be incorporated into existing non-real-time infrastructure (e.g., an edge device running on Windows or Linux) or in the cloud. More and more companies choose to go an efficient way of using toolchains that allow automatic generation of C or IEC 61131-3 code, .NET components, or standalone executables, like this international manufacturer of packaging and paper products that used predictive maintenance software to reduce waste and machine downtime in its plastics manufacturing plants.

4. Making the business case for predictive maintenance. The major question that every company must be able to answer before even getting started with predictive maintenance is, how will I generate revenue with this?

If you cannot answer this “magic question,” all the efforts you are making to build an elaborate predictive maintenance solution will quickly stall. Knowing your business case and having a strategy for monetizing predictive maintenance will help convince your company’s management to justify the investment in implementing a predictive maintenance application.

While for equipment operators the fact that their equipment is less likely to fail during operation typically justifies the investment, the case for equipment builders is a bit more challenging. Some promising ideas that I have seen to help with building a case for implementing predictive maintenance are

- tying service fees to predictive maintenance of the equipment run by the operators (i.e., their customers);

- selling the deployed predictive maintenance algorithm itself using IP protection; and

- shifting to a completely new usage-based business model (e.g., selling cubic meters of compressed air rather than compressors, or elevator usage hours rather than entire elevators).

To learn more about this topic covered in this blog post, email Philipp H. F. Wallner, Industry Manager, Industrial Automation & Machinery, MathWorks, at pwallner@mathworks.com or check out the links:

- Predictive Maintenance (video series): Learn more about predictive maintenance concepts and workflows.

- Using Simulink to Generate Fault Data (example): This example shows how to use a simulation model to generate fault and healthy data. It uses a transmission system and models a gear tooth fault, sensor drift fault, and shaft wear fault.

- Mondi Implements Statistics-Based Health Monitoring and Predictive Maintenance for Manufacturing Processes with Machine Learning (customer reference): See how Mondi Gronau reduced waste and machine downtime in its plants, resulting in more than 50,000 euros saved per year.

- Introduction to Predictive Maintenance with MATLAB (ebook): Learn how to develop your predictive maintenance, condition monitoring, and anomaly detection algorithms.